How to Effectively Plan and Budget for the Production of a New Collection

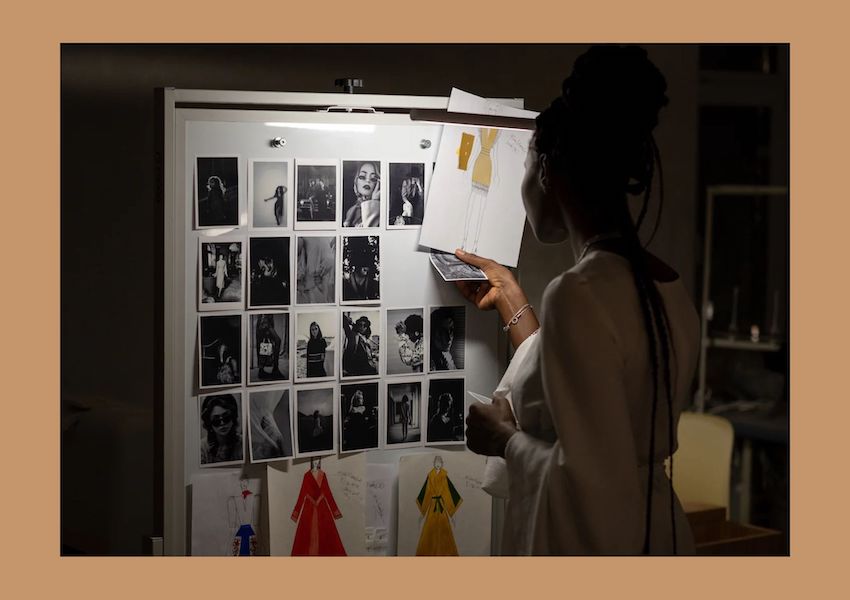

Planning a production budget for a fashion brand requires careful consideration of various factors to ensure efficient resource allocation and successful execution. Designing and developing a collection involves translating creative ideas into tangible designs by sketching, creating patterns or samples, and sourcing high-quality materials. This also requires a significant upfront financial investment to cover the costs of materials, labor, equipment, shipping, and more.

It is crucial for creative directors or brand managers of wholesale brands to thoroughly research and plan for these costs to ensure a successful and sustainable collection. Proper budgeting and financial planning will help in managing expenses and maximizing profits in the long run.

As with anything to do with finances, it is not uncommon for unexpected costs to arise, from design alterations to unforeseen delays and fees. In light of this, it’s important to have a financial buffer or reserve to help navigate any unpredictable situations that may emerge.

Below, we’ve laid out some guidelines to help plan help you plan an effective production budget for a new season.

Review the data

Evaluate the previous year’s finances in terms of sales, production costs, and overall financial performance. Analyzing what worked and what didn’t, identifying successful products and collections, and understanding customer preferences will help you plan better.

Use the information you have to help set business goals and objectives for the upcoming year, such as revenue targets, market expansion, or new product launches. Aligning your production plans with these goals to ensure they support your overall business strategy.

Determine your production costs

To make informed sales projections, break down the costs associated with production, including materials, labor, manufacturing, packaging, and shipping Request up-to-date quotes from the suppliers and manufacturers you work with to accurately estimate production costs.

These costs can be divided into two categories: initial costs and ongoing costs. Initial costs include expenses such as materials, labor, shipping, and equipment. Materials encompass fabrics, trims, buttons, and other components needed for garment production. Labor costs involve hiring skilled workers or outsourcing production to a manufacturing facility. Shipping costs cover transportation of materials and finished products. Equipment costs comprise machinery, tools, and technology required for production.

Ongoing costs consist of website maintenance and marketing expenses, lookbooks that showcase the new products and materials to engage with customers. Marketing costs include online and offline advertising, social media campaigns, influencer collaborations, and trade shows to increase brand visibility and attract customers.

Artisans working on SELFI designs

Allocate your resources

Determine the number of new designs or collections you plan to introduce and allocate a budget for designing, prototyping, and producing them. Assess the complexity of your designs; pieces that require intricate patterns, specialized techniques, or customizations will incur higher production costs compared to simple and straightforward designs.

The cost of materials is also crucial as high-quality or specialty fabrics tend to be more expensive. Additionally, the quantity of materials required for each garment also affects the overall production cost. Labor costs are also a key consideration. Skilled labor is essential for producing high-quality garments, and their expertise comes at a price.

Factor in a portion of your budget for marketing and promoting your products to reach a wider audience and drive sales. such as digital marketing, influencer collaborations, or showroom events.

Account for unexpected costs

Set aside a portion of the budget for unexpected costs or emergencies that may arise during the production process. If sustainability is a priority, allocate a budget for sustainable sourcing, eco-friendly materials, and ethical labor practices.

Monitor and adjust

Regularly track your actual expenses against the budget to ensure you’re on track. Make adjustments if necessary based on changes in demand, production costs, or market conditions. Also, consider consulting with a financial advisor or an industry expert to ensure your budget aligns with industry standards and best practices.